X41 - Μαγνητικά Τσοκ Τραπέζια για Ρεκτιφιέ Μόνιμα

από Ls

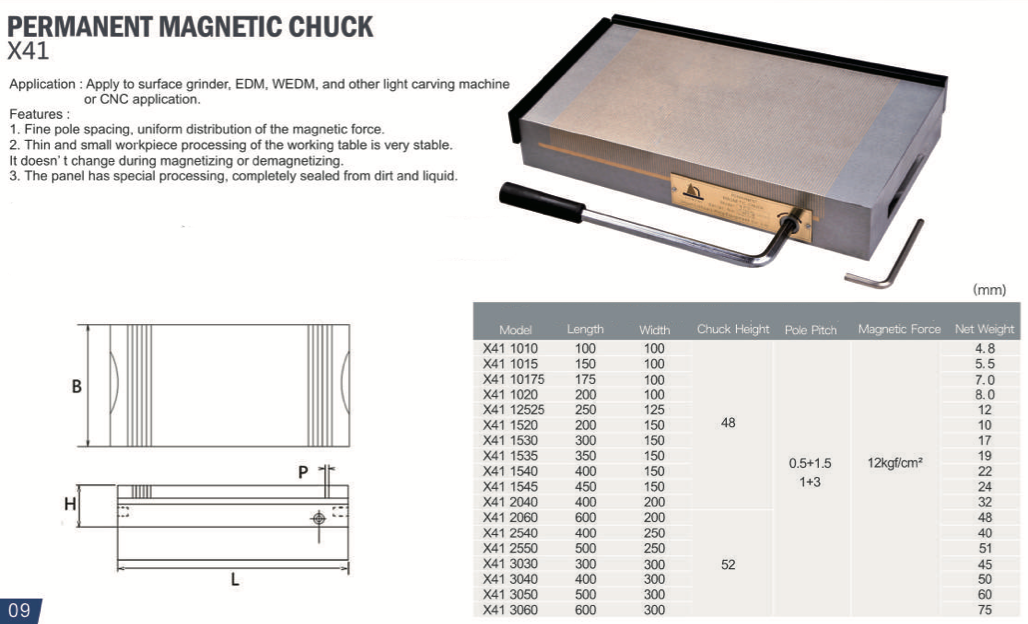

| Κωδικός | Διαστάσεις | Τιμή ** | Στοκ | ||

|---|---|---|---|---|---|

| X41 1010 | 100 x 100 mm | €203,00 | Με παραγγελία | ||

| X41 10175 | 175 x 100 mm | €240,00 | Με παραγγελία | ||

| X41 12525 | 250 x 125 mm | €324,00 | Με παραγγελία | ||

| X41 1520 | 200 x 150 mm | €288,00 | Με παραγγελία | ||

| X41 1530 | 300 x 150 mm | €339,00 | 1 διαθέσιμo | ||

| X41 1535 | 350 x 150 mm | €380,00 | Με παραγγελία | ||

| X41 1540 | 400 x 150 mm | €408,00 | Με παραγγελία | ||

| X41 1545 | 450 x 150 mm | €449,00 | Με παραγγελία | ||

| X41 2040 | 400 x 200 mm | €610,00 | Με παραγγελία | ||

| X41 2060 | 600 x 200 mm | €951,00 | Με παραγγελία | ||

| X41 2540 | 400 x 250 mm | €711,00 | Με παραγγελία | ||

| X41 2550 | 500 x 250 mm | €1.150,00 | Με παραγγελία | ||

| X41 3030 | 300 x 300 mm | €846,00 | Με παραγγελία | ||

| X41 3040 | 400 x 300 mm | €1.183,00 | Με παραγγελία | ||

| X41 3050 | 500 x 300 mm | €1.407,00 | Με παραγγελία | ||

| X41 3060 | 600 x 300 mm | €1.641,00 | Με παραγγελία | ||

Τιμές χωρίς ΦΠΑ 24%

A permanent magnetic chuck for grinding is a type of workholding device used in grinding machines. It is designed to securely hold ferromagnetic workpieces during the grinding process.

The permanent magnetic chuck consists of a magnetized surface with a grid of magnetic poles. When the chuck is energized, it creates a magnetic field that attracts and holds the workpiece in place. This provides a strong and stable grip, ensuring that the workpiece remains securely positioned during grinding operations.

The main advantages of using a permanent magnetic chuck for grinding include:

1. Secure Workholding: The magnetic force exerted by the chuck ensures that the workpiece remains firmly held in place, preventing movement or shifting during grinding. This helps maintain precision and accuracy in the grinding process.

2. Quick and Easy Setup: Magnetic chucks offer a convenient and efficient setup process. Workpieces can be quickly placed and secured on the chuck, saving time and improving productivity.

3. Increased Accessibility: The magnetic chuck allows for full access to the top surface of the workpiece, enabling complete grinding coverage without obstruction.

4. Reduced Tooling Requirements: With the use of a magnetic chuck, there is no need for clamps or fixtures to hold the workpiece, reducing the need for additional tooling and setup.

Permanent magnetic chucks are commonly used in various grinding applications, such as surface grinding, cylindrical grinding, and tool and cutter grinding. They are widely utilized in industries such as manufacturing, automotive, aerospace, and tooling.

It's important to ensure proper handling and maintenance of magnetic chucks to preserve their magnetic strength and overall performance.

The permanent magnetic chuck consists of a magnetized surface with a grid of magnetic poles. When the chuck is energized, it creates a magnetic field that attracts and holds the workpiece in place. This provides a strong and stable grip, ensuring that the workpiece remains securely positioned during grinding operations.

The main advantages of using a permanent magnetic chuck for grinding include:

1. Secure Workholding: The magnetic force exerted by the chuck ensures that the workpiece remains firmly held in place, preventing movement or shifting during grinding. This helps maintain precision and accuracy in the grinding process.

2. Quick and Easy Setup: Magnetic chucks offer a convenient and efficient setup process. Workpieces can be quickly placed and secured on the chuck, saving time and improving productivity.

3. Increased Accessibility: The magnetic chuck allows for full access to the top surface of the workpiece, enabling complete grinding coverage without obstruction.

4. Reduced Tooling Requirements: With the use of a magnetic chuck, there is no need for clamps or fixtures to hold the workpiece, reducing the need for additional tooling and setup.

Permanent magnetic chucks are commonly used in various grinding applications, such as surface grinding, cylindrical grinding, and tool and cutter grinding. They are widely utilized in industries such as manufacturing, automotive, aerospace, and tooling.

It's important to ensure proper handling and maintenance of magnetic chucks to preserve their magnetic strength and overall performance.